RS300 Thermal Camera Driver for Raspberry Pi

2025年8月26日rs300-v4l2-driver Guide: Get MINI2 Thermal Imaging Module Working with Raspberry Pi

2025年10月29日For engineering integrators and technical developers, the biggest pain points in thermal imaging projects often lie in prolonged development cycles and uncontrollable costs—especially when working with a thermal camera module. As a professional manufacturer of uncooled infrared modules, we address these core issues with our Mini 384×288/640×512 series thermal imaging module—a semi-finished solution built with self-developed "Falcon" ISP chips (replacing traditional FPGA schemes) and 12μm pixel WLP IR detectors, designed to balance performance, cost, and integration speed for your projects.

1. Hard Parameters That Solve Your Integration Pain Points

Our Mini series thermal module is engineered to meet the strict demands of industrial, automotive, and smart device development, with specs tailored to technical developers’ needs:

- Detector & Resolution: Vanadium oxide uncooled infrared focal plane detectors, available in 384×288 and 640×512 resolutions. The 12μm pixel size ensures high image clarity, while the optional NETD (≤50mK@25℃, F#1.0; ≤40mK for high-precision needs) captures even 0.1℃ temperature differences—ideal for industrial predictive maintenance (e.g., substation gear overheating) and vehicle ADAS.

- Ultra-Compact & Low-Power: At just 21mm×21mm (size) and <8g (weight), this **thermal camera module** fits easily into small devices (e.g., handheld detectors, smart home sensors). Power consumption is equally impressive: MINI 384 uses <0.5W, MINI 640 uses <0.65W—perfect for battery-powered mobile projects.

- Temperature Measurement Accuracy: Covers two ranges (-20℃ to 150℃, 0℃ to 450℃) with precision of ±2℃ or ±2% of readings (whichever is larger), supporting point/line/frame measurement. For wide-dynamic scenarios, it maintains ±5℃ or ±3% accuracy—suitable for both industrial equipment monitoring and consumer electronics.

- Environmental Durability: Operates from -40℃ to 80℃ (storage: -50℃ to 85℃), resists 6.06g random vibration (all axes) and 80g@4ms impact. This ruggedness ensures stable performance in harsh industrial workshops or outdoor automotive environments.

2. Fast Integration: From Debugging to Deployment in Days

We eliminate the hassle of reverse-engineering interfaces with standardized designs and complete tools for our thermal module:

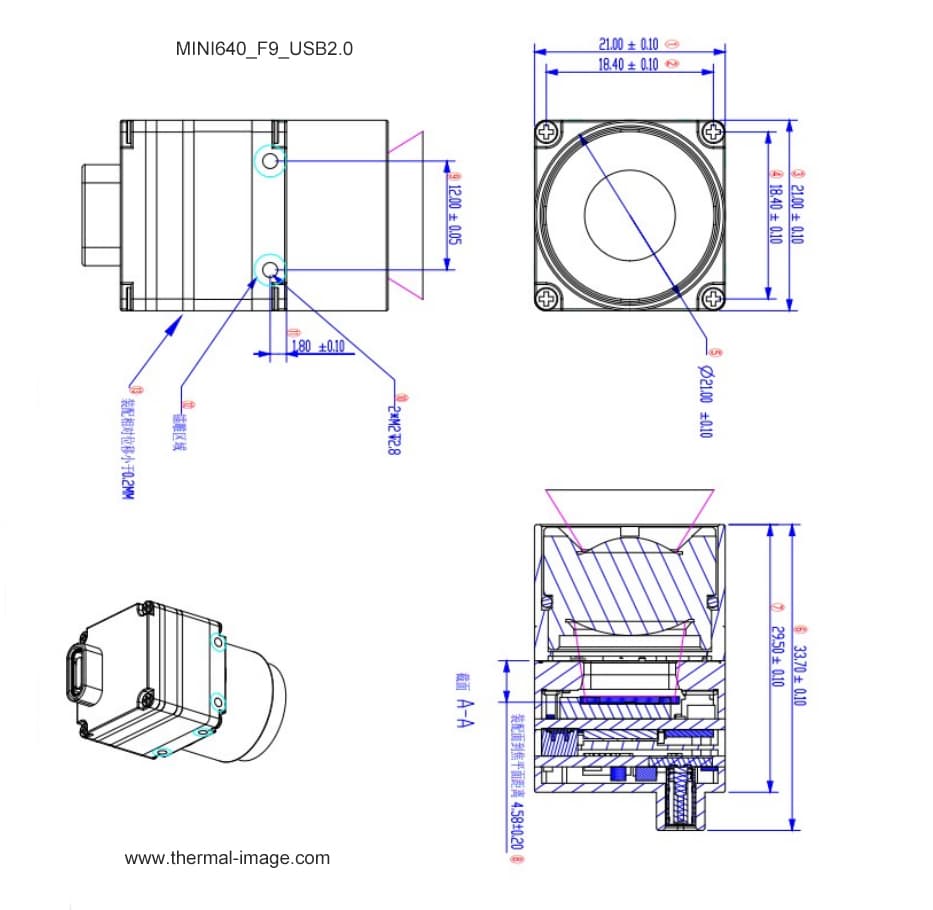

- Versatile Interfaces: The thermal imaging module supports DVP, SPI, and I2C for core data transmission, plus extended options like UART/RS232/RS422 (serial communication), USB, and BT.656 (digital video). For power, it accepts 1.8V/3.3V/5V (simultaneous input) for the module, or 5V-12V (with over-voltage/under-voltage protection and anti-reverse) for the module+expansion board—compatible with STM32, Raspberry Pi, and Jetson Nano.

- Clear Digital Video Support: DVP output offers 14-bit NUC (non-uniformity correction) data and 10-bit DRC (dynamic range compression) data (16-bit transmission), plus 16-bit YUV422 color output (switchable YUYV/YVYU/UYVY/VYUY). We provide detailed timing parameters (e.g., 25Hz/50Hz framerate, 18MHz/24MHz clock for dual-channel 16-bit transmission) to avoid debugging delays.

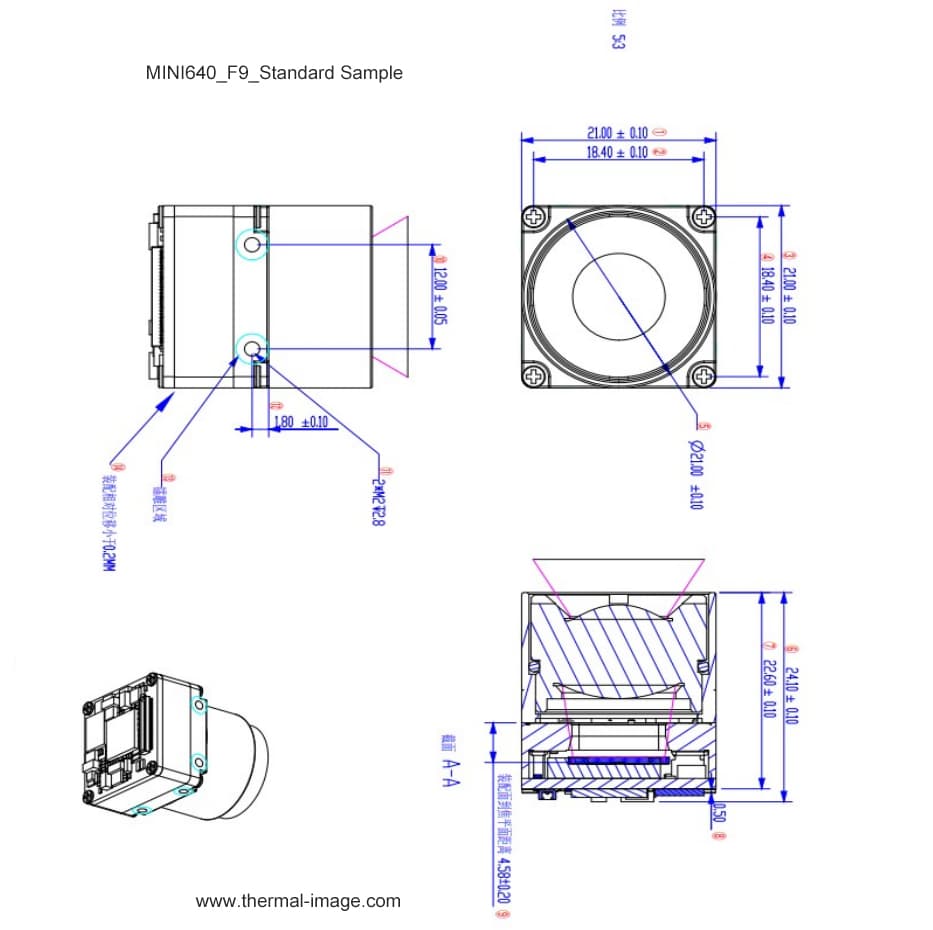

- Complete Development Kit: Every thermal camera module comes with a Hirose 50-connector pin definition table, driver libraries (pre-compiled for mainstream platforms), sample code (for real-time temperature tracing and hot-spot alerting), and mechanical assembly drawings (e.g., 21mm×21mm module dimensions, 4.58±0.20mm focus distance). Most developers finish basic image display and temperature reading debugging in 3-5 days.

3. Cost Control: Self-Developed Chips Cut Expenses by 15%-20%

Unlike traditional thermal module manufacturers relying on expensive FPGA schemes, our Mini series uses self-developed "Falcon" ISP chips—optimizing both performance and cost:

- Chip-Level Cost Reduction: The "Falcon" ISP integrates infrared image processing (TECLESS algorithm, NUC, digital noise reduction, detail enhancement) directly, eliminating the need for external FPGA components. This cuts single-unit costs by 15%-20% compared to non-standardized alternatives.

- Standardized Supply Chain: We use bulk-procured core components (detectors, lenses) and standardized PCB layouts. For orders over 500 units, tiered pricing saves an additional 8%—reducing your prototype and mass-production budgets.

- Flexible Lens Options: Choose from 5mm (FOV 53.3°×39.8°), 6.7mm (40.0°×29.7°), 9.1mm (29.2°×21.7°), 13.5mm (19.6°×14.7°), or 18mm (14.7°×11.0°) fixed-focus athermalization lenses—no need to customize lenses for different scenarios, further lowering costs.

4. Support That Goes Beyond Delivery

We don’t just sell thermal module—we support your entire development cycle:

- Customizable Extension: Design user-specific extension components (e.g., custom interfaces, mechanical enclosures) based on your application (e.g., automotive ADAS, smart home security).

- Technical Training & Debugging: Our team (with 5+ years of thermal imaging module experience) provides free training for your engineers and responds to debugging queries (e.g., algorithm optimization, interface compatibility) within 24 hours.

- Reliable After-Sales: The Mini series comes with a product warranty, and we offer professional maintenance for faults—no need to worry about post-deployment issues.

Ready to Test? Get Your Tailored Sample Today

Stop letting vague specs or slow integration hold back your project. Our Mini 384×288/640×512 thermal camera module are built for engineers like you—with the hard parameters, tools, and support to turn ideas into products fast.

- Apply for a Sample: Specify your needs (384×288/640×512 resolution, lens type) to get a thermal imaging module, full development kit, and 30-minute one-on-one technical consultation (we’ll walk you through driver installation and timing setup).

- Consult Custom Solutions: Need a smaller size, extended temperature range, or custom interface? Our team delivers a preliminary plan within 48 hours—no upfront fees.

Start your low-cost, fast-integration thermal imaging project today—apply for your sample now!

1 Comment

Dear ladies and gentlemen,

I want to buy 1 or 2 thermal cameras plus 2 lenses. I want to buy in china. Please send me the prices for the following items:

- camera 640x480, 9mm

- camera 384 x288, 9mm

- special board for Raspberry Pi connection

- lens 13,5mm

- lens 18mm

If you have a TaoBao / shop how to order, please tell. Purchase will be made through a partner in China.

Prices in Yuan and main land china shipping is fine.

Thank you so much in advance!

Best regards!

Tobias